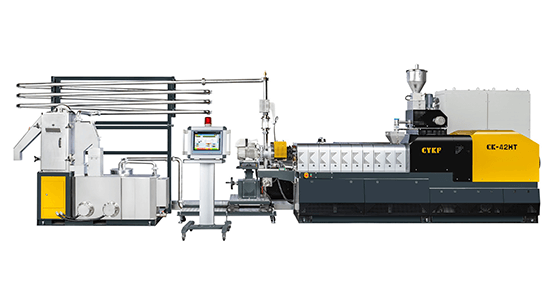

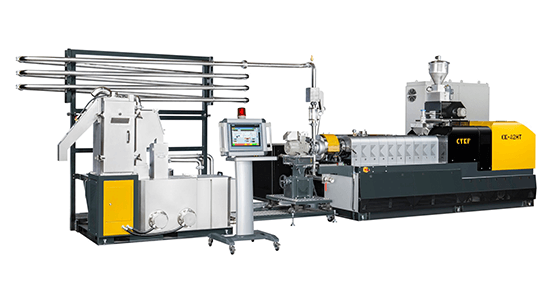

CK-42HT Co-rotating Twin Screw Laboratory Extruder

Preface:

The development of experimental extruders encompasses material variability, prompting CYKF's Vice President, Mr. Xu, to jest, "Our experimental machine is growing up."

Background:

CYKF once again received an invitation from a major domestic petrochemical plant. Due to the customer's excellent prior experience with CYKF's co-rotating twin-screw underwater pelletizing production line and bolstered by positive industry recommendations, their willingness for repeat collaboration surged, prompting a renewed partnership with CYKF.

During initial project discussions, it was revealed that the customer had recent material development needs and required an experimental extruder for research purposes. Given the high precision demanded by the customer's experiments, they expected the equipment's feeding system to have precise proportional delivery. Additionally, they sought a granulation system that suited the diverse nature of their experiments.

Customer Requirements:

- Experimental extruder for material development

- Improved accuracy in the feeding system's delivery

- Configuration of a granulation system suitable for diverse material processes

Solution/Machine Features:

I. Diverse Experimental Formulations, Optimal with CK-HT Series

The experimental extruder, given the complexity and diversity of material formulations, finds suitability in the CK-HT series of co-rotating twin-screw extruders. These employ a modular screw configuration, allowing effective adjustments for material processing.

Moreover, the CK-HT series introduces models for low production volumes. Compared to larger production models, these occupy less space and consume less power. Their lower kilogram output is adequate for research and educational purposes.

Click the link to view the CK-HT Experimental Machine Series.

II. Multi-Directional Feeding System for High Precision Delivery

This experimental extruder features three primary material feeding ports and two side feeding ports for introducing additives during the process.

Given the varied forms of experimental raw materials (powder, liquid, and particle), to ensure precise feeding despite differences in density, CYKF has equipped the machine with a high-precision feeding system capable of adjusting feeding rates for different raw materials.

III. Exceptional Integration Capabilities, Mastering Control

CYKF evaluates customer needs to configure the most suitable equipment for the machine. While not always proprietary, the functionality always aligns best with customer requirements. In instances where customers specify particular branded equipment, CYKF integrates these seamlessly.

For this experimental extruder, CYKF has integrated third-party feeding system equipment, synchronizing the complete process control and management through a unified human-machine interface system.

IV. Highly Compatible Granulation System, Convenient Interchangeability

Given the customer's previous purchase of underwater pelletizing equipment, this time, additional strand-cutting granulation equipment has been provided to expand the customer's material research needs.

CYKF's granulation system equipment boasts high compatibility, allowing for easy and straightforward interchangeability based on material characteristics. Furthermore, additional strand-cutting granulation equipment can be configured based on specific demands.

V. Smooth Process, Consistent Quality

Experimental extruders, required for research purposes, need adequate stability and high controllability to adapt to diverse material processes.

Hence, CYKF's specially designed screws for the experimental extruder enhance process stability. During actual testing, CYKF employed different granulation systems for different materials, ensuring a remarkably smooth process and uniformly shaped particles, leaving the customer highly satisfied.

Reference the test machine video for more insights.

Extension/Conclusion:

When initially developing experimental extruders, CYKF aimed to accommodate small experimental spaces by continuously refining mechanical designs. Their objective was to provide maximum convenience within minimal space, facilitating exploration in the uncharted realm of materials. To date, the experimental extruders offer sufficient flexibility to respond to diverse processing needs, prompting Mr. Xu, CYKF's Vice President, to jokingly remark, "Our experimental machines are growing up."

The 2022 Taipeiplas marks the inaugural display of the experimental extruder.