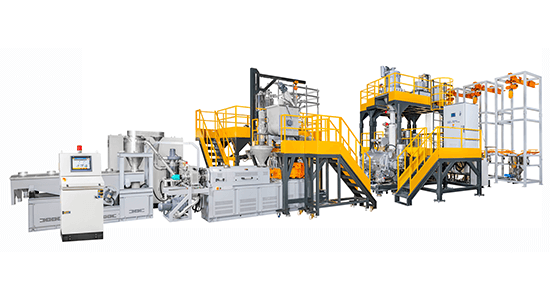

CK-95DT Medical Grade PVC Pelletizing Extrusion Line

Introduction:

CYKF overcomes the challenges in PVC processing through profound mechanical and material expertise, developing a complete factory output line for medical-grade PVC composite materials. This facilitates both the mass production of medical-grade PVC for clients and the experimental processes they require.

Background:

CYKF undertakes a significant domestic project from a leading PVC manufacturer. After team discussions, it was revealed that the client is researching special medical-grade PVC materials and seeks to expand production for medical applications. Simultaneously, they aim to maintain R&D capabilities in equipment to tackle varied specifications and proportions for future tests assessing the feasibility and stability of different medical material applications.

Due to PVC's thermal sensitivity and susceptibility to process variables, this project necessitates a large-scale integrated system to synchronously meet the client's material processing conditions and R&D needs. Moreover, as the produced ester pellets are intended for the medical industry, the process requires heightened caution, significantly elevating the project's complexity.

Client Requirements:

Medical-grade PVC extrusion production line.

Material processing achieving high uniform mixing.

Process flexibility for adjusting specifications and proportions for production.

Solution/Machine Features:

I. PVC Process-Specific - CK-DT Series

The CK-DT series employs a specialized twin-screw extruder for PVC processing. Unlike co-rotating twin-screw extruders, PVC processes cannot be adjusted through screw arrangement. Therefore, screw design becomes pivotal in PVC processing.

CYKF designed special screws tailored for PVC processing to prevent excessive heat or shear, which can lead to PVC degradation. The equipment selects corrosion-resistant materials processed in a specialized manner to effectively reduce equipment wear from contact.

Link to CK-DT Series

II. Integrated Feeding System for Diverse Process Specifications

The medical-grade PVC pellet production line integrates comprehensive powder and liquid feeding systems.

The powder feeding system provides three specifications for PVC powder input, while the liquid feeding system accommodates four specifications for plasticizers. This flexibility enables the utilization of various powder and liquid specifications, expanding the range of PVC experimental processes.

Additionally, each feeding system is paired with a weighing system, allowing precise material adjustment and accurate proportional delivery tailored to the required PHR values for production.

III. Integration of Professional High-Speed Mixing for Enhanced Process Mixing Efficiency

Before PVC process materials enter the extruder, the weighed powders and liquids are directed to a high-speed mixer for rapid blending. Through high rotational speeds, materials are uniformly mixed to a stage suitable for the process.

Due to the challenge of incorporating light, low-proportion special additives, CYKF integrates a professional high-speed mixer with adjustable speeds to evenly disperse them within PVC at appropriate temperatures.

IV. Reinforced Process Feeding with Pressure Feeders

Pressure feeders are commonly used for fluffy materials in processes, such as soft PVC or recycled yarn.

As fluffy materials have a lighter density and tend to be soft, inconsistent feeding can occur. CYKF employs pressure feeders to compact materials, ensuring stable entry into the process.

V. Unique One-Stop Service for Entire Plant Equipment Process Integration

This medical-grade PVC pellet production line, serving as a complete PVC plant output equipment, integrates material preparation, feeding, mixing, extrusion, granulation, and storage systems. From integrated design to vendor communication, the entire plant equipment is managed by CYKF's team and controlled through a unified human-machine interface.

CYKF, as an extruder manufacturer, not only produces extruders but also offers comprehensive services, managing upstream, midstream, and downstream entire plant equipment output. Upholding professional standards, every detail is scrutinized to ensure smooth operation for the client.

Link to PVC Automatic Metering Weighing Conveyor Granulation Production Line

Conclusion:

Composite material processes can enhance process performance by adjusting screw configurations based on material properties. In contrast, PVC processes heavily rely on experience and understanding of extrusion processes to assess necessary adjustments for changes in PVC materials.

With abundant material knowledge and adept mechanical design capabilities, CYKF achieves the required uniformity in powder-liquid mixture and precisely controls process temperatures, maintaining PVC production quality. Additionally, the customization and integration of entire plant equipment, complemented by an automatic error detection safety system, not only increase productivity under similar resources but also reduce labor costs and human error rates.

The enormity of this project's challenges led the client to face multiple deadlocks while searching for a suitable partner until being referred to CYKF by industry peers. CYKF is honored to receive recognition from peers and trust from clients, continuously growing amidst new challenges, becoming the most reliable partner for clients.

Link to PVC Medical Grade Entire Plant Output Pellet Production Line Video

CYKF overcomes the challenges in PVC processing through profound mechanical and material expertise, developing a complete factory output line for medical-grade PVC composite materials. This facilitates both the mass production of medical-grade PVC for clients and the experimental processes they require.

Background:

CYKF undertakes a significant domestic project from a leading PVC manufacturer. After team discussions, it was revealed that the client is researching special medical-grade PVC materials and seeks to expand production for medical applications. Simultaneously, they aim to maintain R&D capabilities in equipment to tackle varied specifications and proportions for future tests assessing the feasibility and stability of different medical material applications.

Due to PVC's thermal sensitivity and susceptibility to process variables, this project necessitates a large-scale integrated system to synchronously meet the client's material processing conditions and R&D needs. Moreover, as the produced ester pellets are intended for the medical industry, the process requires heightened caution, significantly elevating the project's complexity.

Client Requirements:

Medical-grade PVC extrusion production line.

Material processing achieving high uniform mixing.

Process flexibility for adjusting specifications and proportions for production.

Solution/Machine Features:

I. PVC Process-Specific - CK-DT Series

The CK-DT series employs a specialized twin-screw extruder for PVC processing. Unlike co-rotating twin-screw extruders, PVC processes cannot be adjusted through screw arrangement. Therefore, screw design becomes pivotal in PVC processing.

CYKF designed special screws tailored for PVC processing to prevent excessive heat or shear, which can lead to PVC degradation. The equipment selects corrosion-resistant materials processed in a specialized manner to effectively reduce equipment wear from contact.

Link to CK-DT Series

II. Integrated Feeding System for Diverse Process Specifications

The medical-grade PVC pellet production line integrates comprehensive powder and liquid feeding systems.

The powder feeding system provides three specifications for PVC powder input, while the liquid feeding system accommodates four specifications for plasticizers. This flexibility enables the utilization of various powder and liquid specifications, expanding the range of PVC experimental processes.

Additionally, each feeding system is paired with a weighing system, allowing precise material adjustment and accurate proportional delivery tailored to the required PHR values for production.

III. Integration of Professional High-Speed Mixing for Enhanced Process Mixing Efficiency

Before PVC process materials enter the extruder, the weighed powders and liquids are directed to a high-speed mixer for rapid blending. Through high rotational speeds, materials are uniformly mixed to a stage suitable for the process.

Due to the challenge of incorporating light, low-proportion special additives, CYKF integrates a professional high-speed mixer with adjustable speeds to evenly disperse them within PVC at appropriate temperatures.

IV. Reinforced Process Feeding with Pressure Feeders

Pressure feeders are commonly used for fluffy materials in processes, such as soft PVC or recycled yarn.

As fluffy materials have a lighter density and tend to be soft, inconsistent feeding can occur. CYKF employs pressure feeders to compact materials, ensuring stable entry into the process.

V. Unique One-Stop Service for Entire Plant Equipment Process Integration

This medical-grade PVC pellet production line, serving as a complete PVC plant output equipment, integrates material preparation, feeding, mixing, extrusion, granulation, and storage systems. From integrated design to vendor communication, the entire plant equipment is managed by CYKF's team and controlled through a unified human-machine interface.

CYKF, as an extruder manufacturer, not only produces extruders but also offers comprehensive services, managing upstream, midstream, and downstream entire plant equipment output. Upholding professional standards, every detail is scrutinized to ensure smooth operation for the client.

Link to PVC Automatic Metering Weighing Conveyor Granulation Production Line

Conclusion:

Composite material processes can enhance process performance by adjusting screw configurations based on material properties. In contrast, PVC processes heavily rely on experience and understanding of extrusion processes to assess necessary adjustments for changes in PVC materials.

With abundant material knowledge and adept mechanical design capabilities, CYKF achieves the required uniformity in powder-liquid mixture and precisely controls process temperatures, maintaining PVC production quality. Additionally, the customization and integration of entire plant equipment, complemented by an automatic error detection safety system, not only increase productivity under similar resources but also reduce labor costs and human error rates.

The enormity of this project's challenges led the client to face multiple deadlocks while searching for a suitable partner until being referred to CYKF by industry peers. CYKF is honored to receive recognition from peers and trust from clients, continuously growing amidst new challenges, becoming the most reliable partner for clients.

Link to PVC Medical Grade Entire Plant Output Pellet Production Line Video