inquiry

Single Screw Pelletizing Extruder

Description

CK-HS series Single Screw Extruder can be applied to wide applications, e.g., masterbatch, compounding, and recycling. The screw rotational speed is second only to our CK-DHS high-throughput series.

Possible materials :

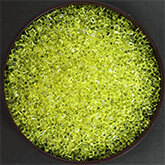

PP, HDPE, LDPE, PS, ABS, ABS & PC, PC, PA, PET, PBT, etc.

-

Extruder screw :

The extruder screw of CYKF’s single screw extruder is customized to satisfy different material formulations. The optimal configuration of screw zones ensures high-efficiency extrusion performance. The strict quality management guarantees good quality and long service life of this critical component. -

Die :

The die material and mold runner must be selected and designed according to the physical properties and characteristics of plastics to avoid occurrences of uneven material flow rate, retention, excessive molding pressure, in-mold temperature increase, decomposition and carbonization or other situations that may damage material properties of plastics.

Features

1. Competitive production capacity

The throughput of CYKF’s single screw extruder is very competitive due to its unique screw design. The steady performance of our extrusion system brings outstanding economic benefits to customers.

2. Combination of various automatic auxiliary systems

CYKF builds automatic single screw extrusion line for customers. From upstream to downstream equipment, our technical team is capable of integrating a complete and automatic extrusion line to satisfy diverse demands.

3. Highly praised by customers in medical industry

CYKF’s single screw extruder is very popular in the market due to its durability, stability, high output and superb mixing behavior. This type of plastic extruder is widely used in various applications, and especially earns highly praises by customers in medical industry who produce meltblown nonwoven fabrics and nose wire for surgical mask. The top 3 manufacturers of meltblown nonwoven fabrics in Taiwan, all purchased our single screw extruders to support their daily operations.

4. Diverse options

There are 4 models of our CK-HS series. Please contact us immediately for more product information. Specification

| Model | CK-HS85 | CK-HS100 | CK-HS120 | CK-HS135 |

|---|---|---|---|---|

| Screw Diameter (mm) | 85 | 100 | 120 | 135 |

| L/D Ratio | 32 - 36 | 32 - 36 | 32 - 36 | 32 - 36 |

| Main Motor (kW) | 75 | 110 | 160 | 200 |

| Output (kg/hr) | 200 - 300 | 300 - 450 | 500 - 750 | 700 - 1000 |

*Above data is based on ABS. Actual output depends on different materials.

*All specifications, design and characteristics shown above are subject to change without prior notice.