Side Force Feeder Type

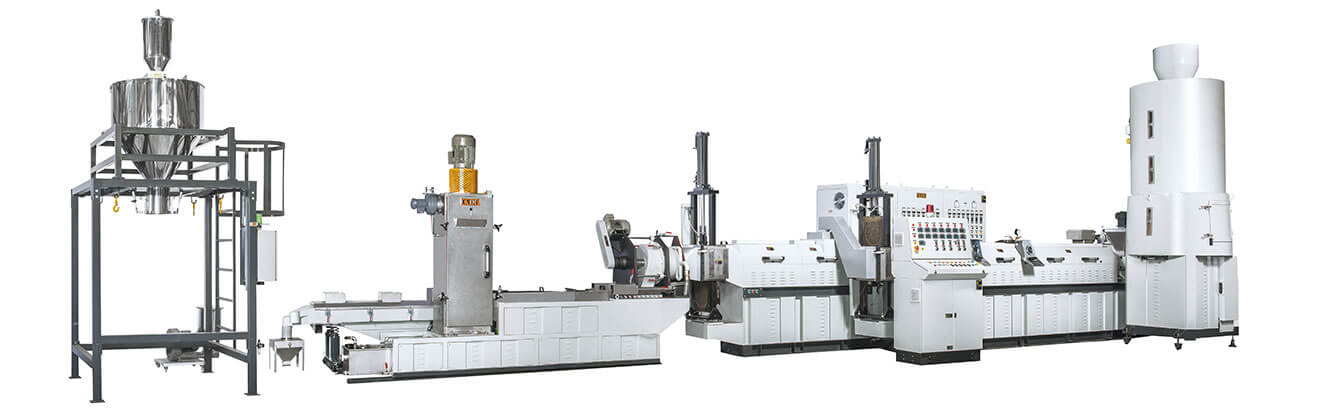

Double Section Recycling Pelletizing Extrusion Line

Description

CK-SFD series Side Force Feeder Type Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic crushed films.

Possible materials :

EPE, EPP, EPS, PP, HDPE, LDPE, ABS, PS crushed films or flakes.

How It Works :

①Side force feeder ➜ ②1st Plastic extruder ➜ ③2nd Plastic extruder ➜ ④Water ring pelletizing system ➜ ⑤Centrifugal dryer ➜ ⑥Vibrating screening unit ➜ ⑦Automatic big bag filling system

Side force feeder is to feed crushed plastic films into plastic extruder. Since the recycled plastics are dirty, the melts must be processed twice by extruder to maintain quality. By repeating process of melting, kneading, and filtering, it ensures impurities of the melts are removed during extrusion. The melts then pass through water ring pelletizing system to be cut into pellets. The pellets are cooled, dried, and screened to become reusable resources.

-

Side force feeder

The crushed plastic films are fed into plastic extruder via side force feeder. The equipment can effectively increase feeding capacity of films.

-

Extruder screw

Extruder screw is the heart of the plastic extruder. The screw design, material, and machining accuracy are going to determine production efficiency and material quality.

-

Water ring pelletizing system

Water ring pelletizing system is widely used, but it is not suitable for sticky, low-viscosity materials because pellets can stick together before they hit the water. When the molten polymer exits the die holes and is cut into pellets by rotating knives in air. The pellets produced outwards are cooled by water and then transported to downstream centrifugal dryer.

-

Centrifugal dryer

The equipment is to eliminate surface moisture on pellets. It is located after pelletizing machine.

-

Vibrating screening unit

The unit can screen out different sizes of plastic pellet to ensure a good average quality of the materials.

-

Automatic big bag filling system

The system enables efficient filling of bulk bags with automatic system. It is stable and easy for operation. It’s an ideal equipment for large-size packaging of materials.

Features

1. Double degassing design

The 1st and 2nd plastic extrusion machine equipped with double degassing system can greatly remove moisture and waste gas from the melts. It also stabilizes extrusion process to ensure quality of materials.

2. Hydraulic screen changer system

The hydraulic screen changer system is a very important equipment for recycling dirty plastics. The screen changer uses dual-cavity piston which can be matched with different filter meshes to achieve high-quality filtering effects. The simple-operation system makes replacement easy and fast.

3. High-capacity screw design

The tailor-made extruder screw brings competitive productivity. The wear resistance of the screw material guarantees a long service life. With its superb mixing behavior and dispersion, CYKF’s recycling machine can effectively reduce loss of material physical properties during extrusion. The recyclate can be used to manufacture products with lower request of material properties to achieve long-term economic benefits for both customers and global environment.

4. High-level human-machine interface

The high-level human-machine interface integrates and controls all manufacturing steps. It helps operators analyze and monitor production parameters. The safety warning system ensures workers staying in a safe working environment. The smart, durable, stable, and efficient CYKF plastic recycling machines can make daily work and maintenance easier and faster.

5. Various options

The CK-SFD series has 4 models. Different pelletizing systems and auxiliary equipment are available on request. Please contact us immediately for more product information. Specification

| Model | CK-SFD100 | CK-SFD120 | CK-SFD135 | CK-SFD150 |

|---|---|---|---|---|

| Screw Diameter (mm) | 100 | 120 | 135 | 150 |

| L / D Ratio | 32 - 36 | 32 - 36 | 32 - 36 | 32 - 36 |

| Main Motor (kW) | 75 | 110 | 132 | 160 |

| Output (kg/hr) | 200 - 250 | 250 - 350 | 350 - 450 | 400 - 600 |

*Above data is based on PE film recycling. Actual output depends on different materials.

*All specifications, design and characteristics shown above are subject to change without prior notice.