Double Section Recycling Pelletizing Extrusion Line

Description

CK-HSD series Double Section Plastic Recycling Pelletizing Line is ideal for recycling dirty plastic flakes.

Possible materials :

PP, PE, ABS, PS, POM, PC, PA, PMMA, PBT, PET, etc.

How It Works :

①Force feeder ➜ ②1st Plastic extruder ➜ ③2nd Plastic extruder ➜ ④Strand pelletizing system (Water tank ➜ Strand dryer ➜ Pelletizing machine) ➜ ⑤Vibrating screening unit ➜ ⑥Storage tank

Force feeder is designed to feed plastic flakes into the single screw plastic extruder without causing bridging. Since the recycled wastes are dirty, they must be melted, kneaded, and filtered in the extruder twice to keep the purity, and then pass through strand pelletizing system to be cooled, pelletized, dried, and screened before becoming usable pellets again.

-

Force feeder

The design of the force feeder is able to avoid any possible bridging during recycled flakes are fed into the plastic extrusion machine.

-

Extruder screw

Extruder screw is the heart of the plastic extruder. The function of the screw is to melt, deliver, and knead plastics. From steel selection, machining to quality management, we have strict standard procedures to ensure a long service life of this critical component.

-

Water tank

After the plastic is extruded into strips from the die of the extruder, the strips enter the water tank and are cooled and formed by water. The cooled strips are then dried and cut into pellets. The length of the tank can be customized according to request.

-

Strand dryer

The strand dryer is to remove surface moisture on the cooled plastic strips. There are 2 stages of the dewatering process. The 1st stage is to absorb most of the moisture on plastic strip surfaces, and the 2nd stage is to dry the strips by blower.

-

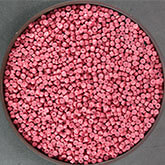

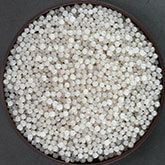

Plastic pelletizer

The pelletizing machine is to cut plastic strips into pellets. The unique round knife design has extremely high wear resistance and can exert outstanding cutting performance.

-

Vibrating screening unit

The equipment can screen out different sizes of pellets and remove dust on pellet surface.

-

Storage tank

The storage tank is to gather plastic pellets. It is made by stainless steel and has different capacities can be selected. Big bag filling machine or bagging machine are also available on request.

Features

1. Vacuum degassing system

The vacuum degassing system can sufficiently devolatilize moisture and waste gas of recycled materials. It can also stabilize extrusion process.

2. High-throughput screw design

The customized extruder screw brings competitive throughput. Its superb mixing behavior and dispersion can effectively reduce loss of material physical properties during extrusion. The wear resistance of screw material guarantees a long service life. By using CYKF’s plastic recycling machine, the recyclate can be used as a secondary material to produce goods with lower request of material properties. It can bring profit for customers and benefit to global environment.

3. Hydraulic screen changer system

The hydraulic screen changer system is a very important equipment for recycling dirty plastics. The screen changer uses dual-cavity piston which can be matched with different filter meshes to achieve high-quality filtering effects. The simple-operation system makes replacement easy and fast.

4. Durability, stability, high productivity

Durability, stability, and high productivity are the features of CYKF’s equipment. It is why we keep earning fine reputations from customers around the world.

5. Diverse options

The CK-HSD series has 5 models. Different plastic pelletizing systems and auxiliary equipment are available on request. Please contact us immediately for more product information. Specification

| Model | CK-HSD85 | CK-HSD100 | CK-HSD120 | CK-HSD135 | CK-HSD150 |

|---|---|---|---|---|---|

| Screw Diameter (mm) | 85 | 100 | 120 | 135 | 150 |

| L / D Ratio | 34 - 36 | 34 - 36 | 34 - 36 | 34 - 36 | 34 - 36 |

| Main Motor (kW) | 75 | 110 | 132 | 160 | 200 |

| Output (kg/hr) | 150 - 250 | 250 - 350 | 300 - 500 | 400 - 650 | 500 - 800 |

*Above data is based on ABS recycling. Actual output depends on different materials.

*All specifications, design and characteristics shown above are subject to change without prior notice.